-

Telefone : +8618150976625

-

E-mail : Hello@MicrofiberLeather.com

Telefone : +8618150976625

E-mail : Hello@MicrofiberLeather.com

Eu defino couro sintético como um material sintético criado para ter a aparência e o toque de couro genuíno. Os fabricantes costumam usar poliuretano (PU), cloreto de polivinila (PVC), náilon ou poliéster para produzi-lo. Este material não contém ingredientes de origem animal. produtos e depende de componentes à base de petróleo. Na indústria têxtil, frequentemente o vejo chamado por vários nomes:

couro sintético

couro vegano

Couro sintético é um material feito pelo homem que imita a aparência e o toque do couro real sem usar produtos de origem animal.

Tipos comuns de couro sintético incluir Couro PU, Couro de PVC, e microfibra, cada um com propriedades e usos únicos.

O couro sintético é mais acessível do que o couro genuíno, o que o torna uma escolha popular nos setores de moda, automotivo e de móveis.

Enquanto o couro sintético é amigo dos animais, pode não ter durabilidade nem respirabilidade em comparação ao couro real.

Estão surgindo alternativas ecológicas ao couro sintético tradicional, usando materiais vegetais ou reciclados para reduzir o impacto ambiental.

O couro sintético é fácil de manter, exigindo apenas um pano úmido para limpeza, o que atrai consumidores ocupados.

A crescente demanda por couro sintético reflete uma mudança em direção a escolhas de moda sustentáveis e éticas entre os consumidores.

Ao escolher couro sintético, considere o uso pretendido, a aparência desejada e a durabilidade necessária para obter os melhores resultados.

Descrevo o couro sintético como um material versátil que reproduz a aparência e o toque do couro genuíno. Os fabricantes usam tecnologia avançada para criar este produto artificial, que frequentemente vejo rotulado como couro sintético, couro sintético ou tecido de couro sintéticoO processo envolve a combinação de uma base de tecido, geralmente poliéster, com um revestimento de poliuretano (PU) ou policloreto de vinila (PVC). Esses componentes químicos conferem ao couro sintético sua durabilidade e flexibilidade.

O couro sintético se tornou um produto básico em indústrias como moda, automotiva e de móveis devido à sua boa relação custo-benefício e composição sem ingredientes de origem animal.

Costumo me referir aos principais componentes químicos na produção de couro sintético. A tabela a seguir resume esses materiais:

Componente químico | Descrição |

|---|---|

Poliuretano (PU) | Um material polimérico comumente usado, conhecido por suas excelentes propriedades, amplamente aplicado em vários setores. |

Cloreto de polivinila (PVC) | Outro tipo de plástico usado em couro sintético, que difere do PU no processo de fabricação. |

Na última década, observei um crescimento significativo no mercado de couro sintético. A demanda por tecido de couro sintético continua a subir, especialmente na região da Ásia-Pacífico. A tabela a seguir mostra a tendência do valor de mercado:

Ano | Valor de mercado (US$ bilhões) | CAGR (%) |

|---|---|---|

2024 | 43,46 | N / D |

2025 | 46,74 | N / D |

2033 | 83,60 | 7,54 |

A região Ásia-Pacífico deverá ser o maior mercado para couro sintético, com um valor esperado de US$ 31.208 milhões até 2030 e um CAGR de 8,95%.

A Europa deverá ser o segundo maior mercado, com um valor esperado de US$ 14,73 bilhões até 2030 e um CAGR de 6,75%.

Quando eu comparo couro artificial em relação ao couro verdadeiro, notei várias diferenças importantes. Couro artificial, incluindo falso tecido de couro, é feito de materiais sintéticos como PU e PVC. O couro legítimo vem de peles de animais, tornando-se um subproduto natural da indústria da carne.

Origem do material: O couro verdadeiro é um subproduto natural, enquanto o couro sintético é feito de materiais artificiais.

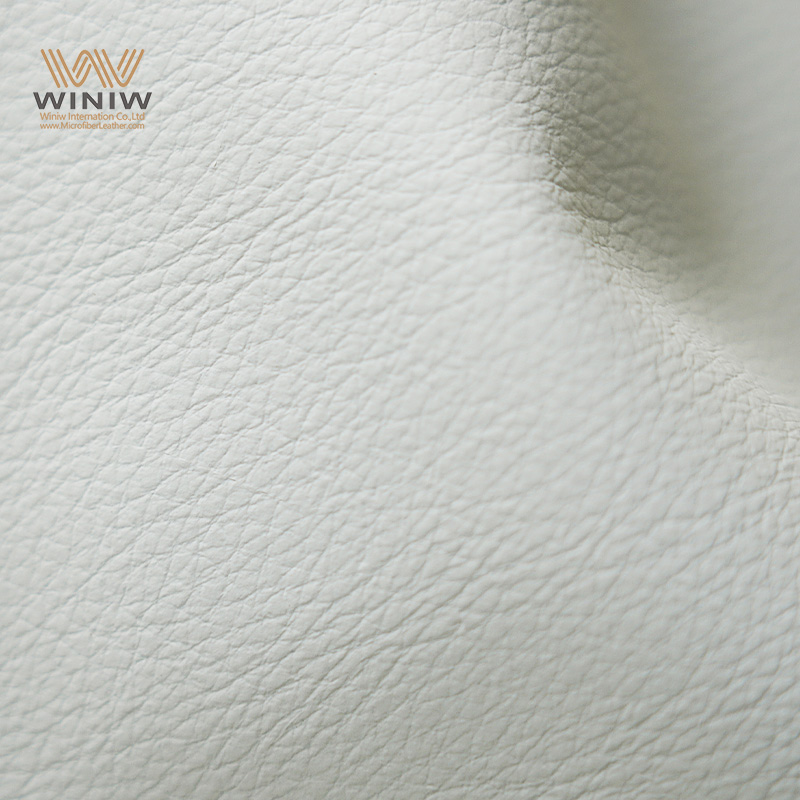

Sensação da superfície: O couro sintético geralmente tem uma superfície emborrachada ou brilhante. O couro legítimo apresenta grãos e textura naturais.

Temperatura: O couro sintético é mais frio ao toque. O couro legítimo é mais quente.

Odor: O couro legítimo tem um cheiro característico. O couro sintético pode ter um odor de plástico.

Teste de queima: Materiais sintéticos queimam mais facilmente, encolhendo e enrolando. O couro legítimo não reage da mesma forma.

Etiquetagem: Os produtos devem indicar claramente se são feitos de materiais sintéticos, distinguindo-os do couro verdadeiro.

Também considero os processos de fabricação. O couro legítimo requer um processo complexo de curtimento, frequentemente utilizando curtimento vegetal, que é lento e produz características únicas. O curtimento ao cromo oferece rapidez, mas levanta questões éticas. O couro artificial, por outro lado, utiliza materiais sintéticos prensados sobre um tecido base. Esse processo é rápido, permite a produção em massa e garante uma cor uniforme, mas pode resultar em menor durabilidade ao longo do tempo.

O impacto ambiental desempenha um papel importante na minha avaliação. O couro artificial, feito de materiais sintéticos como poliéster ou náilon, depende de combustíveis fósseis, que não são renováveis. O couro legítimo, como subproduto da indústria alimentícia, é considerado renovável. O couro legítimo tende a durar mais, o que o torna mais sustentável para o meio ambiente. O couro sintético, por outro lado, é menos durável e frequentemente acaba em aterros sanitários devido a desafios de reciclagem.

Costumo confundir couro vegano com tecido de couro sintético. Os padrões da indústria ajudam a esclarecer esses termos. O couro vegano é feito de materiais de origem vegetal e foca em fontes sustentáveis e éticas. O couro sintético é normalmente feito de produtos à base de petróleo, como PU e PVC, priorizando a relação custo-benefício.

Recurso | Couro Vegano | Couro do falso |

|---|---|---|

Material | Feito de materiais de origem vegetal | Feito de produtos à base de petróleo |

Processo de produção | Foca no fornecimento sustentável e ético | Muitas vezes produzido com foco na relação custo-eficácia |

Impacto Ambiental | Geralmente mais ecológico | Pode ter um impacto ambiental significativo devido ao uso de plástico |

Durabilidade | Mais durável do que o couro sintético típico | Varia, mas geralmente é menos durável que o couro vegano |

Consideração ética | Livre de crueldade e sustentável | Imita principalmente couro sem produtos de origem animal |

O couro vegano é feito de materiais orgânicos, enquanto o couro sintético é feito de materiais sintéticos como PU e PVC.

O couro vegano enfatiza a sustentabilidade e a produção ética. O couro sintético se concentra em imitar a aparência do couro legítimo a um custo menor.

O couro sintético pode ser menos durável quando comparado ao couro vegano, que tende a durar mais.

O couro sintético é feito de materiais plásticos, que podem ser prejudiciais ao meio ambiente, enquanto o couro vegano é feito de materiais orgânicos.

O couro vegano é considerado mais sustentável e tem menor impacto ambiental quando comparado ao couro sintético.

O couro sintético é frequentemente usado por sua acessibilidade e variedade, enquanto o couro vegano é escolhido por suas implicações éticas.

O couro vegano surgiu na indústria da moda com foco em fontes éticas e sustentabilidade, rejeitando práticas que prejudicam o meio ambiente e os animais. O couro sintético, por outro lado, costuma ser produzido com menos preocupação com esses fatores, visando principalmente replicar a aparência do couro legítimo a um preço mais baixo.

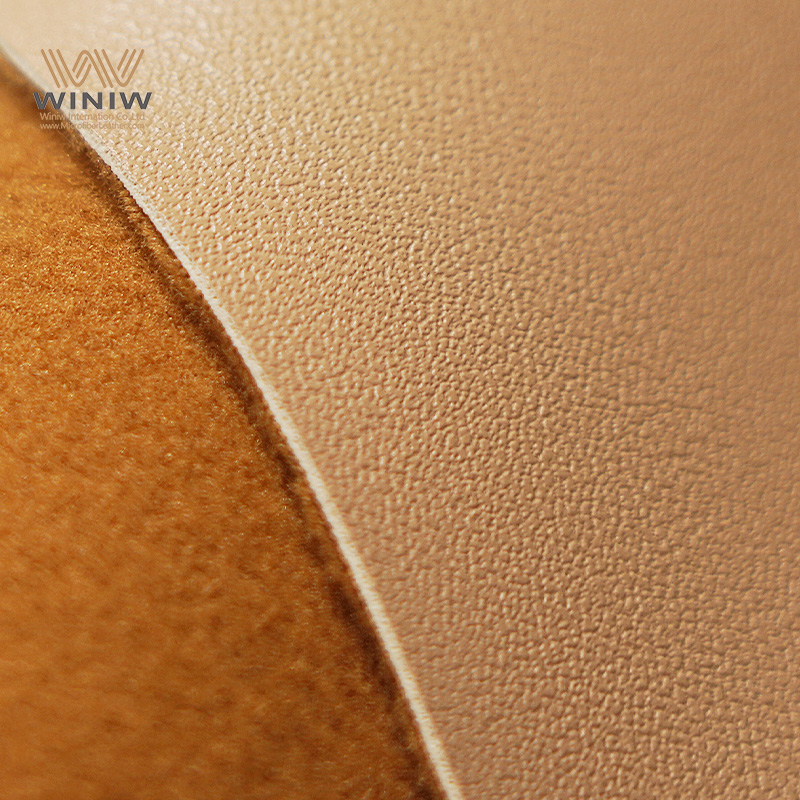

Quando examino a produção de couro sintético, vejo um processo altamente organizado que combina tecnologia e química. Começo com uma base de tecido, geralmente poliéster ou algodão, que fornece estrutura e flexibilidade. O processo começa com o revestimento dessa base com: poliuretano (PU) ou cloreto de polivinila (PVC). Este revestimento cria a aparência e o toque característicos do couro sintético.

Observo várias etapas importantes na produção de couro artificial:

Preparação do Tecido Base: Eu seleciono um tecido poroso e áspero, geralmente poliéster ou algodão, para garantir forte adesão.

Aplicação de revestimento: Aplico uma camada líquida de PU ou PVC ao tecido usando maquinário avançado. Esta etapa determina a espessura e a textura do produto final.

Relevo e impressão: Eu uso máquinas de estampagem para imprimir padrões na superfície, imitando a textura do couro legítimo. Máquinas de impressão adicionam variações de cor e design.

Cura e Acabamento: Eu curo o tecido revestido em altas temperaturas para fixar o material. Máquinas de tombamento amaciam o produto, deixando-o com uma textura mais próxima do couro legítimo.

Confio em máquinas especializadas para alcançar qualidade consistente na produção de couro sintético. As máquinas mais comuns incluem:

Máquinas de tombamento para amaciamento e texturização.

Linhas de produção computadorizadas de PU/PVC com estampagem on-line para produção de alto volume.

Máquinas de impressão da Itália e Taiwan para diversos designs.

Máquinas de estampagem com rolos de aço e vácuo para padrões realistas.

Esse processo me permite produzir grandes quantidades de tecido de couro sintético de forma eficiente, com controle preciso sobre cor, textura e espessura.

Presto muita atenção ao materiais usados em couro sintético Fabricação. A escolha do tecido base e do material de revestimento afeta diretamente a qualidade e o desempenho do produto final.

Tecido de base | Características |

|---|---|

Algodão | Poroso e áspero |

Poliéster | Poroso e áspero |

Costumo usar poliéster como base principal porque oferece durabilidade e flexibilidade. O algodão serve como alternativa para aplicações específicas que exigem um toque mais macio.

Para o revestimento, escolho entre couro PU e PVC. O PU proporciona uma textura mais macia, semelhante à do couro, enquanto o couro PVC oferece maior resistência à umidade e à abrasão. O couro sintético de poliuretano se destaca por sua capacidade de imitar de perto a aparência e o toque do couro verdadeiro.

No entanto, reconheço as preocupações ambientais e de saúde associadas a esses materiais:

O couro sintético depende de plásticos como PU e PVC, que exigem uma quantidade significativa de produtos químicos e água durante a produção.

O processo de fabricação libera gases de efeito estufa e polui o ar e os cursos d'água.

Produtos de PVC podem conter altos níveis de chumbo, representando sérios riscos à saúde.

A maioria do couro vegano, apesar de sua imagem ecológica, usa plásticos não biodegradáveis que contribuem para o desperdício em aterros sanitários.

Eu sempre levo esses fatores em consideração ao selecionar materiais para produção de couro artificial.

Quando alguém me pergunta "como é feito o couro sintético", explico o processo passo a passo. Começo com uma base têxtil não tecida, geralmente poliéster, e a impregno com poliuretano. Essa etapa fixa o revestimento ao tecido, conferindo ao material sua resistência e flexibilidade.

O processo de colagem desempenha um papel crucial na determinação da durabilidade e textura do tecido de couro sintético:

Eu uso materiais de PU ou vinil para obter uma textura mais macia, parecida com couro.

O couro sintético PU funciona bem para estofados residenciais porque se assemelha muito ao couro verdadeiro.

Ao contrário do couro sintético, o tecido de couro sintético resiste ao desbotamento e aos danos causados pelos raios UV.

Tipo de couro | Durabilidade | Textura |

|---|---|---|

Couro do falso | Mais durável que couro colado | Mais macio, mais parecido com couro |

Couro colado | Descasca e desbota rapidamente | Textura menos atraente |

Acho que o couro sintético, feito de PU ou PVC, oferece um equilíbrio entre aparência e desempenho. A qualidade do processo de colagem influencia diretamente a durabilidade do material e a sensação de realismo. O couro sintético não tem o cheiro característico do couro legítimo, mas é fácil de limpar e repele líquidos com eficácia.

Quando trabalho com couro sintético, costumo escolher Couro sintético PU Por sua aparência realista e textura macia, o couro PU utiliza uma camada de poliuretano aplicada a uma base de tecido, geralmente poliéster ou algodão. Esse processo cria um material que imita o couro legítimo, tanto na aparência quanto no toque. Encontro couro PU em muitos itens de moda, como jaquetas, bolsas e sapatos, porque é confortável e tem um visual sofisticado.

Aqui está uma tabela que destaca as principais características do couro PU em comparação com outros tipos de tecido de couro sintético:

Característica | Couro PU | Outros couros sintéticos |

|---|---|---|

Composição do material | Feito com uma camada de poliuretano sobre tecido | Vários materiais sintéticos |

Aparência | Mais realista, assemelha-se muito ao couro real | Varia amplamente em textura e estética |

Custo | Geralmente mais caro devido à maior qualidade | Disponível em uma faixa de preço mais ampla |

Prefiro couro sintético PU quando preciso de flexibilidade e respirabilidade. É macio e permanece confortável mesmo com uso prolongado. No entanto, notei que o couro PU não tem um desempenho tão bom quanto o couro PVC em condições climáticas extremas. Ele pode se desgastar mais rápido se exposto a condições adversas. Apesar disso, o PU continua sendo uma escolha popular para muitos tipos de couro sintético devido ao seu equilíbrio entre conforto e estilo.

O couro sintético de PVC, também conhecido como couro de PVC, destaca-se por sua durabilidade e resistência à água. Costumo usar esse tipo de couro artificial em produtos que exigem resistência, como móveis para áreas externas, estofados automotivos e alguns tipos de acessórios de couro sintético. O couro de PVC utiliza cloreto de polivinila como revestimento principal, o que o torna mais resistente à umidade e à abrasão do que o couro de PU.

Aqui estão algumas vantagens e desvantagens que observei no couro sintético de PVC:

Vantagens:

Durável e duradouro

À prova d'água e resistente às condições aquáticas

Desvantagens:

Menos confortável que o couro PU

Má ventilação e sensação de frio na pele

Recomendo couro sintético de PVC quando preciso de um material que resista ao uso intenso e à exposição à água. No entanto, evito-o para roupas ou itens que ficam em contato com a pele por longos períodos, pois não possui a maciez e a respirabilidade do couro PU. Quando comparo os tipos de couro sintético, o couro de PVC oferece resistência, mas sacrifica o conforto.

O tecido de couro sintético de microfibra representa uma nova geração de materiais artificiais. Eu uso microfibra quando quero combinar a maciez do PU com a durabilidade do PVC. Couro de microfibra Utiliza fibras sintéticas ultrafinas, frequentemente entrelaçadas em uma base densa e não tecida. Essa estrutura confere ao couro de microfibra um equilíbrio único entre flexibilidade, resistência e aparência.

Acho que o tecido de couro sintético de microfibra se destaca por vários motivos:

É macio e suave, muito parecido com couro PU de alta qualidade.

Ele resiste ao desgaste, o que o torna adequado para áreas de tráfego intenso.

Mantém sua aparência ao longo do tempo, mesmo com uso frequente.

O couro de microfibra funciona bem tanto na moda quanto em estofados. Costumo usá-lo para sapatos, bolsas e móveis que precisam ter boa aparência e durabilidade. Comparada a outros tipos de couro sintético, a microfibra oferece um meio-termo entre conforto e resistência. Considero-a um dos tipos de couro sintético mais versáteis disponíveis atualmente.

Aqui está uma tabela resumindo os principais tipos de couro sintético encontrados no mercado global:

Tipo de couro sintético | Descrição |

|---|---|

Baseado em biologia | Derivado de fontes naturais, como resíduos agrícolas (por exemplo, talos de banana, cactos, cascas de manga, resíduos de abacaxi). |

Poliuretano (PU) | Um material sintético comum usado para diversas aplicações. |

Cloreto de polivinila (PVC) | Outro sintético amplamente utilizado material de couro. |

à base de água | Um tipo de couro sintético que utiliza água como solvente em sua produção. |

Dica: Ao escolher entre PU, PVC e microfibra, sempre considero o uso pretendido, a aparência desejada e a durabilidade necessária. Cada tipo de couro artificial oferece benefícios únicos para diferentes aplicações.

Tenho observado uma demanda crescente por couro artificial ecológico nos últimos anos. Muitas marcas e fabricantes buscam alternativas sustentáveis ao couro sintético tradicional. Acredito que essa mudança decorre da maior conscientização sobre as questões ambientais e o impacto dos materiais derivados do petróleo. O couro artificial ecológico utiliza materiais inovadores de origem vegetal ou reciclados, que reduzem a dependência de combustíveis fósseis e minimizam a poluição.

Costumo recomendar opções ecológicas para clientes que desejam reduzir sua pegada de carbono. Essas alternativas oferecem benefícios e desafios únicos. Compilei uma tabela que resume os materiais de couro artificial mais comuns, seus processos de produção e principais características:

Material Alternativo | Descrição | Processo de produção | Características |

|---|---|---|---|

Sobremesa | Feito de cacto pera espinhosa, economiza água e é usado em vários itens de moda. | Não requer produtos químicos nocivos nem água em excesso. | Boa aceitação na indústria da moda, usado por marcas como Balenciaga e Hublot. |

Malai | Feito de resíduos agrícolas do processamento de coco, lembra couro. | Utiliza águas residuais em um processo de fermentação. | Biodegradável, mas vulnerável à umidade. |

Casca de maçã | Feito de cascas e caroços de maçãs descartados, tem uma textura semelhante à do papel. | Incorpora PU à base de água. | Usado por marcas como VEERAH, mas não confirmado como biodegradável. |

Mylo | Couro de cogumelo, anteriormente considerado um material promissor. | A produção foi interrompida devido à falta de investimento. | Potencial para menor impacto ambiental. |

Trabalhei com couro de cacto Desserto em vários projetos. Este material me impressiona pela sua textura macia e durabilidade. O processo de produção utiliza pouquíssima água e evita produtos químicos tóxicos. Percebi que marcas de luxo como Balenciaga e Hublot agora usam Desserto em suas coleções. Vejo isso como um sinal de que o couro artificial ecológico pode atender a altos padrões de qualidade e estilo.

O Malai, feito a partir de resíduos de coco, destaca-se pela sua biodegradabilidade. Admiro o fato de o processo de produção utilizar águas residuais e fermentação, o que reduz os danos ambientais. No entanto, descobri que os produtos Malai podem ter dificuldades em climas úmidos. Aconselho os clientes a considerarem isso ao escolher materiais para uso externo.

A Apple Skin oferece outra alternativa interessante. Os fabricantes usam cascas e caroços de maçã descartados, combinando-os com poliuretano à base de água. Já vi marcas como a VEERAH adotarem a Apple Skin para calçados e acessórios. O material tem textura semelhante à do papel, o que confere aos produtos um visual único. Não confirmei se a Apple Skin é totalmente biodegradável, então sempre consulto os fornecedores antes de recomendá-la para projetos com foco ecológico.

O Mylo, feito de cogumelos, já se mostrou muito promissor. Acompanhei seu desenvolvimento de perto, mas a produção foi interrompida devido a dificuldades de investimento. Ainda acredito que o couro de cogumelo pode se tornar uma opção ecológica de ponta se a indústria investir em mais pesquisas.

🌱 Incentivo meus clientes a explorar o couro artificial ecológico. Esses materiais ajudam a reduzir o impacto ambiental e apoiam a moda sustentável. Acredito que a inovação nessa área continuará a crescer, oferecendo mais opções para marcas e consumidores que se preocupam com o planeta.

Sempre lembro aos meus clientes que cada alternativa ecológica possui propriedades únicas. Sugiro considerar o uso pretendido, o clima e os requisitos de durabilidade antes de tomar uma decisão. O couro artificial ecológico representa um passo positivo em direção a um futuro mais sustentável nos setores da moda, automotivo e moveleiro.

Quando eu comparo couro sintético para couro real, concentro-me em como cada material resiste ao uso diário. O couro legítimo me impressiona por sua capacidade de se tornar mais macio e confortável com o tempo. Percebo que ele resiste ao desgaste, especialmente quando bem cuidado. O couro sintético, incluindo o couro artificial e o couro sintético, frequentemente apresenta sinais de rachaduras e fissuras após uso prolongado. A vida útil do couro sintético costuma ser menor do que a do couro legítimo.

Testei diferentes tipos de couro sintético em estudos de abrasão. Couro sintético revestido de PU Apresenta bom desempenho contra abrasões planas e flexíveis. Resiste à formação de bolinhas e mantém sua aparência por mais tempo do que as variedades sem revestimento. O couro sintético texturizado sem revestimento de PU resiste apenas à abrasão flexível e à formação de bolinhas. Isso significa que alguns couros sintéticos podem se igualar ao couro legítimo em termos de durabilidade, mas a maioria não dura tanto.

Aqui está uma tabela que resume os principais fatores que considero ao comparar esses materiais:

Fator | Couro legítimo | Couro do falso |

|---|---|---|

Qualidade | Produto natural com características únicas | Cor consistente feita à máquina |

Durabilidade | Resistente, torna-se mais macio com o tempo | Rachaduras e rachaduras mais facilmente, vida útil mais curta |

Manutenção | Fácil de cuidar com manutenção adequada | Requer mais cuidado, menos durável |

Dica: Recomendo sempre verificar o tipo de couro sintético utilizado. Opções com revestimento de PU oferecem maior durabilidade para produtos do dia a dia.

Presto muita atenção às qualidades visuais e táteis de ambos os materiais. O couro legítimo se destaca por suas imperfeições naturais e textura única. Cada peça é macia e flexível, proporcionando uma experiência luxuosa. O couro sintético, por outro lado, tem uma aparência mais uniforme. Os fabricantes criam cores e texturas consistentes, que podem não ter as características do couro legítimo.

O cheiro também diferencia esses materiais. O couro legítimo tem um aroma agradável e natural. O couro sintético, especialmente os à base de PVC, costuma ter cheiro de plástico. Acho que o couro sintético oferece mais opções de cores, o que atrai designers que buscam variedade.

Aqui está uma tabela que destaca as diferenças que notei:

Recurso | Couro legítimo | Couro Sintético (Falso) |

|---|---|---|

Aparência | Aparência natural com imperfeições únicas | Aparência mais uniforme e menos natural |

Textura | Suave e flexível | Pode ser suave, mas geralmente menos flexível |

Cheiro | Aroma natural e agradável | Cheiro de plástico para couro de PVC |

Opções de cores | Opções de cores limitadas | Mais opções de cores disponíveis |

Observação: escolho couro sintético quando preciso de uma cor específica ou de um acabamento impecável. Para artigos de luxo, prefiro a aparência e o toque únicos do couro legítimo.

Considero o impacto ambiental um fator-chave na minha tomada de decisão. A produção de couro legítimo envolve emissões significativas de carbono, especialmente quando se considera as atividades agrícolas. A pegada de carbono do couro bovino atinge cerca de 110,0 kg de CO2e por metro quadrado. A produção de couro sintético, incluindo os tipos PU e PVC, resulta em uma pegada de carbono muito menor — cerca de 15,8 kg de CO2e por metro quadrado. Isso torna o couro sintético quase sete vezes menos impactante em termos de emissões de gases de efeito estufa.

O couro verdadeiro requer criação de animais, o que contribui para o desmatamento e as emissões de metano.

O couro sintético depende de materiais à base de petróleo, mas sua produção emite menos gases de efeito estufa.

Vejo marcas migrando para o couro sintético ecológico para reduzir sua pegada ambiental.

🌱 Recomendo aos clientes que considerem o couro sintético para projetos onde a sustentabilidade é importante. A redução das emissões de carbono o torna uma escolha responsável para muitos setores.

Ao avaliar o custo do couro sintético em comparação ao couro legítimo, noto uma diferença significativa nos preços. O couro sintético oferece consistentemente uma alternativa mais acessível. Os fabricantes produzem couro sintético usando processos industriais em larga escala, o que reduz os custos de produção. O couro legítimo, por outro lado, requer peles de animais, curtimento especializado e artesanato especializado. Esses fatores elevam o preço dos produtos de couro legítimo.

Costumo aconselhar os clientes a considerarem seu orçamento antes de escolher entre esses materiais. O couro sintético atrai muitos consumidores porque lhes permite desfrutar da aparência e do toque do couro sem o alto custo. O preço acessível do couro sintético contribuiu para sua popularidade nos setores de moda, automotivo e mobiliário. Vejo marcas lançando linhas inteiras de produtos usando couro sintético para atingir consumidores preocupados com o orçamento.

Observação: O aumento do custo do couro legítimo restringiu o poder de compra do consumidor. Muitos compradores agora preferem o couro sintético por seu preço mais baixo e durabilidade comparável.

Tenho observado que a diferença de preço entre o couro sintético e o couro legítimo continua aumentando. Os preços do couro legítimo flutuam devido a fatores como a oferta de gado, a demanda global e as regulamentações ambientais. Os preços do couro sintético permanecem estáveis porque os fabricantes dependem de matérias-primas consistentes, como PU e PVC. Essa estabilidade torna o couro sintético uma escolha confiável para empresas que precisam gerenciar custos.

Aqui está uma tabela que resume a comparação de custos:

Material | Faixa de preço médio (por jarda) | Custos de manutenção | Demanda de mercado |

|---|---|---|---|

Couro legítimo | $ 50 – $ 250 | Alto | Decrescente |

Couro sintético | $ 10 – $ 30 | Baixo | Aumentando |

Acho que o couro sintético não só custa menos no início, como também economiza dinheiro ao longo do tempo. A manutenção do couro sintético é simples. Limpo com um pano úmido e evito condicionadores ou tratamentos caros. O couro legítimo requer cuidados regulares, incluindo condicionamento e proteção contra umidade. Esses custos contínuos se somam, tornando o couro legítimo menos prático para muitos consumidores.

A vantagem econômica do couro sintético vai além do comprador individual. As empresas se beneficiam de custos de material mais baixos, o que lhes permite oferecer preços competitivos. Tenho visto fabricantes de móveis e montadoras migrar para o couro sintético para reduzir despesas e aumentar as margens de lucro. Essa mudança impulsionou o crescimento do mercado de couro sintético em todo o mundo.

Reconheço que algumas marcas de luxo ainda preferem couro legítimo por seu prestígio e qualidades únicas. No entanto, a maioria das marcas tradicionais prioriza preços acessíveis. O couro sintético atende a essas necessidades, mantendo uma aparência elegante.

Considero o couro sintético um pilar fundamental na indústria da moda. Designers contam com esse material para criar jaquetas, saias, calças e vestidos estilosos. Costumo escolher o couro sintético por sua versatilidade e capacidade de imitar o visual luxuoso do couro legítimo. Marcas usam couro sintético para produzir bolsas, cintos, carteiras e chapéus. Esse material permite uma ampla gama de cores e acabamentos, o que me ajuda a criar designs únicos que se destacam no mercado.

Eu percebo que tecido de couro sintético Oferece diversas vantagens na moda. Resiste a manchas e umidade, tornando-o adequado para o uso diário. Admiro sua facilidade de limpeza e manutenção, especialmente em comparação com o couro legítimo. Muitos consumidores preferem o couro sintético por ser uma alternativa livre de crueldade animal, sem abrir mão do estilo. Tenho observado a demanda por aplicações em couro sintético crescer rapidamente, especialmente entre os consumidores mais jovens, que valorizam a sustentabilidade e o preço acessível.

Indústria | Aplicações |

|---|---|

Indústria da Moda | Bolsas, cintos, carteiras, sapatos, acessórios |

Indústria de Calçados | Botas, Sandálias, Tênis, Outros calçados |

Produtos de estilo de vida | Capas de celular, carteiras, pulseiras de relógio, acessórios |

Dica: Recomendo couro sintético para projetos de moda que exigem durabilidade, cores vibrantes e origem ética.

Utilizo couro sintético extensivamente na fabricação de móveis e estofados. Este material reveste sofás, poltronas, bancos e almofadas em residências, escritórios e espaços públicos. O couro sintético substitui o couro legítimo em salas de espera, instalações médicas e hotéis. Escolho o couro sintético por suas propriedades retardantes de chamas, que atendem aos padrões de segurança em ambientes comerciais e de hospitalidade.

O tecido moderno de couro sintético tem aparência e toque quase idênticos ao couro legítimo. Posso escolher entre uma ampla gama de cores e padrões, o que inspira designs criativos de móveis. O couro sintético proporciona uma estrutura resistente e realça o apelo estético de sofás e cadeiras. Considero que ele suporta o uso diário e não desbota, tornando-o ideal para ambientes com alto tráfego.

Couro sintético reveste vários tipos de assentos, incluindo sofás, poltronas e bancos.

Eu o uso em escritórios, salas de espera e instalações médicas por sua durabilidade.

Os designers de móveis apreciam os designs atraentes e a estrutura forte.

Couro sintético retardante de chamas atende aos requisitos de segurança em hotéis e restaurantes.

Observação: recomendo tecido de couro sintético para projetos de estofamento que exigem estilo e praticidade.

Eu confio em couro sintético para interiores automotivos, incluindo bancos, painéis de portas e apoios de braço. O couro sintético proporciona um visual elegante e moderno que atrai compradores de carros. Escolhi esse material porque é mais acessível do que o couro legítimo e mais fácil de manter. O couro sintético resiste ao desbotamento, manchas e rachaduras, o que garante um desempenho duradouro nos veículos.

Observei que o couro sintético oferece diversos benefícios no design automotivo. Ele simplifica a limpeza e a manutenção, o que é importante para motoristas ocupados. O material mantém sua aparência ao longo do tempo, mesmo com uso frequente. No entanto, continuo ciente das preocupações ambientais relacionadas aos métodos de produção. Nem todo couro sintético é ecológico ou vegano, apesar das alegações de marketing.

Os bancos, painéis e portas do carro são feitos de couro sintético para maior durabilidade.

O material resiste a manchas e rachaduras, tornando-o adequado para interiores automotivos.

Eu escolho couro sintético por sua acessibilidade e estética moderna.

🚗 Recomendo couro sintético para projetos automotivos que exigem equilíbrio entre estilo, conforto e custo-benefício.

Vejo o couro sintético como um divisor de águas no mundo dos acessórios e calçados. Os fabricantes utilizam esse material para produzir uma ampla gama de produtos, incluindo carteiras, cintos, pulseiras de relógio, bolsas e sapatos. Costumo recomendar o couro sintético para esses itens porque ele oferece um equilíbrio entre estilo, durabilidade e preço acessível.

Na minha experiência, o couro sintético se destaca no mercado de acessórios por vários motivos. Ele permite que os designers experimentem cores, texturas e acabamentos difíceis de obter com couro legítimo. Já trabalhei com marcas que usam couro sintético para criar bolsas e carteiras vibrantes. Esses produtos atraem clientes que buscam itens da moda sem o alto custo ou as preocupações éticas associadas ao couro animal.

Os fabricantes de calçados também se beneficiam do couro sintético. Já vi empresas de calçados esportivos usarem couro sintético (PU) em tênis e calçados esportivos. Esse material proporciona flexibilidade e respirabilidade, o que melhora o conforto durante a atividade física. Os fabricantes de calçados sociais escolhem o couro sintético por sua aparência consistente e fácil manutenção. Acho que botas e sandálias de couro sintético resistem melhor à água e manchas do que muitas opções de couro legítimo.

Aqui está uma tabela que compara couro sintético e couro real em acessórios e calçados:

Recurso | Couro sintético | Couro legítimo |

|---|---|---|

Preço | Mais acessível | Caro |

Variedade de cores | Ampla gama de cores e padrões | Tons naturais limitados |

Manutenção | Fácil de limpar, resistente à água | Requer cuidados regulares |

Durabilidade | Bom, mas pode rachar com o tempo | Duradouro, envelhece bem |

Apelo Ético | Opções veganas e sem ingredientes de origem animal | Baseado em animais |

Percebo que o couro sintético atrai um público amplo. Muitos consumidores preferem produtos veganos e livres de crueldade animal. Tenho observado um aumento na demanda por acessórios de couro sintético entre consumidores mais jovens que valorizam a sustentabilidade. As marcas agora comercializam carteiras e cintos de couro sintético como alternativas ecológicas.

Dica: Aconselho os clientes a escolherem microfibra ou couro sintético PU para acessórios que exigem toque macio e alta durabilidade. Esses materiais têm bom desempenho no uso diário e mantêm sua aparência por mais tempo do que as opções básicas de PVC.

Também reconheço as limitações do couro sintético. Alguns produtos podem apresentar sinais de desgaste, como rachaduras ou descascamento, após uso prolongado. Recomendo sempre verificar a qualidade do material antes de comprar. O couro sintético de alta qualidade pode rivalizar com o couro legítimo, tanto em aparência quanto em desempenho.

Trabalho com couro sintético há muitos anos. Vejo vários vantagens claras que o tornam uma escolha popular em todos os setores. O benefício mais significativo é a acessibilidade. Os fabricantes podem produzir couro sintético a um custo menor do que o couro genuíno, o que permite que as marcas ofereçam produtos elegantes a preços acessíveis. Costumo recomendar couro sintético para clientes que desejam a aparência do couro sem o custo.

O couro sintético é amigo dos animais. Não contém produtos de origem animal, o que atrai consumidores que buscam opções livres de crueldade animal. O couro vegano e outras alternativas artificiais apoiam a moda ética e reduzem a dependência da pecuária. Percebo que muitas marcas agora destacam o uso de couro sintético para atrair consumidores ecologicamente conscientes.

A versatilidade do design se destaca como outra grande vantagem. Posso escolher entre uma ampla gama de cores, texturas e acabamentos. O couro sintético se adapta facilmente a diferentes estilos, do clássico ao moderno. Considero-o especialmente útil em design de moda, automotivo e de móveis.

A manutenção é simples. O couro sintético resiste a manchas e umidade, portanto, a limpeza requer apenas um pano úmido. Produtos feitos de couro sintético costumam durar mais em ambientes onde derramamentos e sujeira são comuns. A resistência aos raios UV também ajuda a prevenir o desbotamento, o que mantém os itens com aparência de novos.

A eficiência hídrica e as opções ecológicas melhoraram nos últimos anos. Alguns fabricantes agora usam materiais reciclados ou fontes vegetais para criar couro artificial. Essas inovações reforçam a sustentabilidade do couro sintético e ajudam a reduzir o impacto ambiental.

Dica: Recomendo couro sintético para projetos que exigem preços acessíveis, origem ética e flexibilidade de design.

Aqui está uma tabela que resume as principais vantagens e desvantagens de acordo com pesquisas com consumidores:

Vantagens do couro sintético | Desvantagens do couro sintético |

|---|---|

Amigo dos animais | Durabilidade |

Eficiência Hídrica | Respirabilidade |

Opções ecológicas | Não biodegradável |

Acessibilidade | Falta de pátina |

Resistência UV | Desgaste |

Fácil manutenção | Sensibilidade ao calor |

Versatilidade de design | Poluição por microplásticos |

Apesar dos seus benefícios, o couro sintético tem várias desvantagensA durabilidade continua sendo uma preocupação. Observei que o couro sintético tende a rachar e descascar com o tempo, especialmente com o uso intenso. O couro artificial não desenvolve pátina como o couro legítimo, por isso não possui as características que acompanham o envelhecimento.

A respirabilidade é limitada. O couro sintético não permite a passagem de ar com facilidade, o que pode fazer com que os produtos fiquem quentes e desconfortáveis. Costumo ver esse problema em assentos de carro e roupas. A sensibilidade ao calor também afeta o couro sintético. A exposição a altas temperaturas pode causar deformações ou danos.

As preocupações ambientais persistem. A maior parte do couro sintético não é biodegradável e contribui para a poluição por microplásticos. Mesmo as opções ecológicas, embora melhores, ainda dependem de processos artificiais. A sustentabilidade do couro sintético depende da inovação contínua e da fabricação responsável.

O desgaste aparece mais rápido do que com couro legítimo. Percebo que produtos de couro sintético podem perder a aparência após alguns anos. Para clientes que desejam itens duradouros, sugiro considerar a melhor alternativa ao couro artificial, como couro vegano de alta qualidade ou opções avançadas de microfibra.

Observação: sempre aconselho os clientes a ponderarem os prós e os contras antes de escolher couro sintético. Para alguns usos, a melhor alternativa ao couro artificial pode oferecer melhor desempenho e sustentabilidade.

Defino couro sintético como um material versátil, sem componentes de origem animal, que imita a aparência e o toque do couro legítimo. Já vi fabricantes usarem processos avançados para unir PU ou PVC a bases de tecido, criando produtos que diferem do couro legítimo em durabilidade, custo e impacto ambiental. Uso vários tipos de couro para moda, móveis e automotivo. O couro sintético oferece preço acessível e flexibilidade de design, mas pode não oferecer respirabilidade nem durabilidade a longo prazo. Para muitas necessidades, considero-o uma alternativa prática e ética.

Eu percebo que O couro PU é mais macio e se parece mais com couro legítimo. O couro de PVC oferece maior resistência à água e durabilidade. Eu escolho PU para conforto e estilo, enquanto escolho PVC para uso pesado ou ao ar livre.

Acho que a maioria dos couros sintéticos não pode ser reciclada facilmente. A mistura de plásticos e tecidos dificulta a reciclagem. Algumas novas opções ecológicas usam materiais reciclados, mas os couros tradicionais de PU e PVC geralmente acabam em aterros sanitários.

I couro sintético limpo com um pano úmido e sabão neutro. Evito produtos químicos agressivos ou esponjas abrasivas. Para manchas, seco a área delicadamente. A limpeza regular mantém o material com aparência de novo e evita rachaduras.

Dica: sempre teste os produtos de limpeza primeiro em uma área pequena e escondida.

Percebi que o couro sintético resiste melhor à água do que o couro legítimo. Revestimentos de PU e PVC bloqueiam a umidade. No entanto, evito deixar o material de molho, pois a água pode infiltrar-se pelas costuras ou danificar a base do tecido com o tempo.

Sim, observei que o couro sintético pode rachar ou descascar, especialmente com uso intenso ou exposição à luz solar e ao calor. Opções de PU ou microfibra de alta qualidade duram mais, mas todos os couros sintéticos acabam se desgastando.

Recomendo couro sintético para pessoas com alergia a animais. Ele não contém proteínas animais. No entanto, algumas pessoas podem reagir aos produtos químicos usados na produção. Sempre verifico se há rótulos hipoalergênicos se a segurança for uma preocupação.

Eu uso couro sintético de PVC para móveis de área externa porque ele é resistente à água e aos raios UV. Os tipos de PU e microfibra funcionam melhor em ambientes internos. Sempre verifico as recomendações do fabricante antes de escolher couro sintético para uso externo.

Procuro um toque macio e flexível, costuras uniformes e um padrão de grãos realista. Couro sintético de alta qualidade não tem cheiro forte de plástico. Evito produtos com revestimentos finos ou bordas ásperas.

Observação: a qualidade geralmente depende do processo de fabricação e dos materiais utilizados.